01.What Is Top Dye Fabric?

Top dye fabric is a unique existence in the field of textiles. It is not the traditional way of spinning yarn first and then dyeing, but dyeing the fibers first and then spinning and weaving. Here, we have to mention the key role in top dye fabric - color masterbatch. Color masterbatch is a kind of highly concentrated pigment or dye particles, which is evenly dispersed in the carrier resin. Through the use of specific color masterbatches, various bright and stable colors can be accurately blended, injecting rich color souls into the top dye fabric.

This unique process endows top dye fabric with many advantages. It has a soft and natural color effect, and the color is more uniform, durable, and not easy to fade.

At the same time, the texture of top dye fabric is unique, and the hand feel is comfortable, bringing us an excellent wearing experience. It can also achieve some color combinations and effects that ordinary fabrics are difficult to achieve, providing a broader space for fashion design. Whether it is for making fashionable clothing or for home decoration, top dye fabric can show its unique charm and add a different kind of splendor to our lives.

Top dye fabric is commonly used for making clothes, such as casual pants,men suits, dress and so on,making it suitable for a variety of occasions.

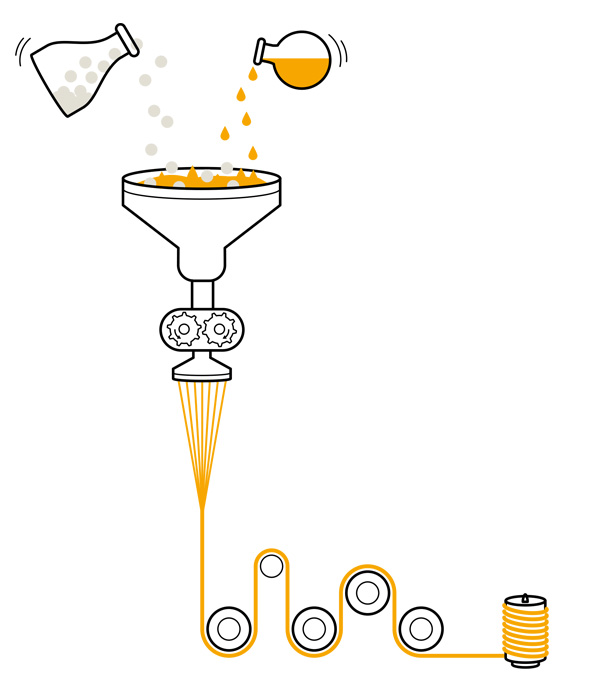

02.The Process Of Top Dye Fabric

① Recycle plastic bottles to make polyester slices

② Polyester slices and color masterbatch are melted at high temperature

③ Complete the colouring and generate colored fibers

④ Spining fiber into yarns

⑤ Weave yarn into fabrics

We specialize in the large-scale production of top dye grey pant fabrics, ensuring both efficiency and quality control. Our extensive inventory of greige (undyed) fabric allows us to transform these materials into finished products within just 2-3 days. For popular colors such as black, gray, and navy blue, we maintain a constant ready goods, ensuring that these shades are always available for immediate orders. Our standard shipping time for these ready-to-ship colors is within 5-7 days. This streamlined process enables us to meet our customers' demands promptly and reliably.If you need to customize other colors and reach a certain quantity, we can make it for you.

03.Top-Dyeing Versus Normal-Dyeing

Top-Dyeing:Color pigments are added to the polymer solution before it is extruded into fibers, integrating the color into the fiber structure.

Normal-Dyeing:Color is added to the fabric or yarn after the fiber has been formed using methods such as vat dyeing, reactive dyeing, or direct dyeing.

Top-Dyeing: Top-dyeing is considered more environmentally friendly. Top dye fabric is environmentally friendly due to its significant reduction in water and chemical usage during production. By adding color to the fibers before they are spun into yarn, it eliminates the need for extensive dye baths and harmful chemical treatments. This process leads to less wastewater pollution, reduced chemical consumption, and lower energy use, making it a more sustainable option compared to traditional dyeing methods.

Normal-Dyeing:Traditional dyeing methods typically require large amounts of water, chemicals, and energy. The dyeing process generates wastewater that needs to be treated to remove harmful substances before it can be released into the environment.

The environmental impact of normal-dyeing can be mitigated through the use of eco-friendly dyes and advanced wastewater treatment technologies, but it generally remains more resource-intensive than solution-dyeing.

Top-Dyeing:Because the color is integrated into the fiber during production, top-dyeing ensures a consistent and uniform color throughout the entire fiber. This results in even coloring in the final fabric or product.

There are fewer issues with dye lot variations, making it easier to achieve color consistency across different production batches.

Normal-Dyeing:Achieving consistent color can be more challenging with normal-dyeing. Variations in dye absorption and application can lead to differences in color intensity and uniformity.

Quality control measures are necessary to ensure that the final product meets color specifications, and there can still be variations between dye lots.

Solution-Dyeing:The color is embedded within the fiber, making it highly resistant to abrasion and other forms of wear and tear.

Normal-Dyeing:The color fastness of normal-dyed fabrics can vary depending on the type of dye used and the fiber's affinity for the dye. Over time, normal-dyed fabrics may experience fading, especially with frequent washing or prolonged exposure to sunlight.

Special treatments and finishes can be applied to improve the color fastness, but they may not match the inherent durability of solution-dyed fibers.

04.The Advantage Of Top Dye Fabric

Eco friendly:

In terms of water conservation,the production process of our top dye stretchable trouser fabric is about 80% more water saving than normal dyed fabric.In terms of exhaust emissions,the production process of top dye fabric 34% less carbon dioxide than normal dyeing fabric.In the use of green energy,the green energy used in the production of top dye fabric is 5 times that of normal dyeing fabric.Not only that,in the production process of top dye fabrics,70% of the sewage can be recycled and reused.

No color difference:

Due to the special process of this fabric, the dyeing process is carried out from the source using masterbatch and fiber melting, so that the yarn itself can have various colors, and it is no longer necessary to add dyes twice in the later process to achieve the dyeing effect. As a result, all batches of textile fabrics have no color difference, generally up to one million meters without color difference, and the fabric can be machine washed and exposed to the sun for a long time without fading. Ensure that buyers and sellers do not have to worry about the quality of the fabrics in the entire transaction process from manufacturing and sales to receipt.

Eco friendly | No color difference | Crisp handfeeling

Crisp handfeeling:

Because the raw material polyester fiber of the fabric itself has natural softness and elasticity, at the same time, its production and weaving process refers to the worsted wool fabric manufacturing, through the machine to enhance the strength and stability of the yarn, so as to further strengthen the crisp degree of the finished fabric, so that the fabric is soft and fluffy and not easy to wrinkle.

At the same time, because of this feature, clothing made of top dye fabrics is easier to care for. Buyers can use washing machines to wash them with confidence without worrying about machine washing affecting the overall shape of the clothing, nor do they need to worry about the clothing being damaged and not durable due to frequent machine washing and drying.

05.Top Two Of Our Top Dye Fabric

We are pleased to introduce two of our most popular top dye fabrics, TH7751 and TH7560.These two are our strengths, polyester rayon spandex fabric

TH7560 is composed of 67% polyester, 29% rayon, and 4% spandex, with a weight of 270 gsm. TH7751, on the other hand, consists of 68% polyester, 29% rayon, and 3% spandex, with a heavier weight of 340 gsm. Both items are 4 way stretch fabric, combining the benefits of polyester and viscose for durability and softness, along with the flexibility provided by spandex.

These fabrics are produced using the top dye process, which ensures superior color fastness, resistance to pilling, and a soft hand feel. We maintain a ready stock of TH7751 and TH7560 in popular colors like black, gray, and navy blue, with shipping typically within 5 days.

Market and Pricing:

These top dye black trouser fabrics are highly sought after in markets across Europe, including the Netherlands and Russia, as well as in the United States, Japan, and South Korea. We offer competitive pricing, making these high-quality fabrics an excellent value.

If you are interested in learning more or placing an order, please do not hesitate to contact us. We look forward to serving your fabric needs.

06.Research And Development Department

Leading innovation

YunAi Textile has been committed to polyester rayon fabric production for many years and has rich experience in fabric manufacturing. Most importantly, it is a great team of professionals who weave the future of the company together with passion and professionalism every day.

Provide customers with impeccable innovative products

This is the commitment we have been committed to since our establishment, guaranteeing and developing a wide range of technical fabrics designed and tested to meet the numerous requirements of customers for formal, sports, and leisure.

Research and development is a continuous process

This is a journey of continuous pursuit of future fabrics, guided by intuition, curiosity and market demand often point us in the direction.

Welcome to contact us for more information