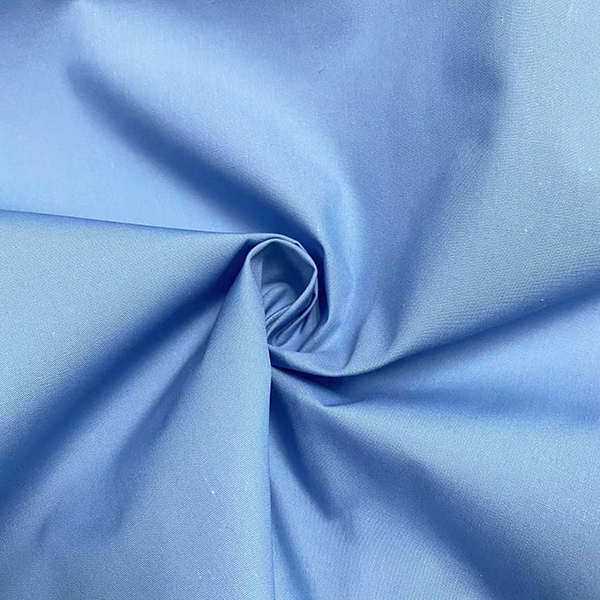

In the world of textiles, the types of fabrics available are vast and varied, each with its own unique properties and uses. Among these, TC (Terylene Cotton) and CVC (Chief Value Cotton) fabrics are popular choices, especially in the apparel industry. This article delves into the characteristics of TC fabric and highlights the differences between TC and CVC fabrics, providing valuable insights for manufacturers, designers, and consumers alike.

Characteristics of TC Fabric

TC fabric, a blend of polyester (Terylene) and cotton, is renowned for its unique combination of properties derived from both materials. Typically, the composition of TC fabric includes a higher percentage of polyester compared to cotton. Common ratios include 65% polyester and 35% cotton, although variations exist.

Key characteristics of TC fabric include:

- Durability: The high polyester content imparts excellent strength and durability to TC fabric, making it resistant to wear and tear. It maintains its shape well, even after repeated washing and usage.

- Wrinkle Resistance: TC fabric is less prone to wrinkling compared to pure cotton fabrics. This makes it a popular choice for garments that require a neat appearance with minimal ironing.

- Moisture Wicking: While not as breathable as pure cotton, TC fabric offers decent moisture-wicking properties. The cotton component helps in absorbing moisture, making the fabric comfortable to wear.

- Cost-Effectiveness: TC fabric is generally more affordable than pure cotton fabrics, offering a budget-friendly option without compromising too much on quality and comfort.

- Easy Care: This fabric is easy to care for, withstanding machine washes and drying without significant shrinkage or damage.

Differences Between TC and CVC Fabric

While TC fabric is a blend with a higher proportion of polyester, CVC fabric is characterized by its higher cotton content. CVC stands for Chief Value Cotton, indicating that cotton is the predominant fiber in the blend.

Here are the key differences between TC and CVC fabrics:

- Composition: The primary difference lies in their composition. TC fabric typically has a higher polyester content (usually around 65%), while CVC fabric has a higher cotton content (often around 60-80% cotton).

- Comfort: Due to the higher cotton content, CVC fabric tends to be softer and more breathable than TC fabric. This makes CVC fabric more comfortable for prolonged wear, especially in warmer climates.

- Durability: TC fabric is generally more durable and resistant to wear and tear compared to CVC fabric. The higher polyester content in TC fabric contributes to its strength and longevity.

- Wrinkle Resistance: TC fabric has better wrinkle resistance compared to CVC fabric, thanks to the polyester component. CVC fabric, with its higher cotton content, may wrinkle more easily and require more ironing.

- Moisture Management: CVC fabric offers better moisture absorption and breathability, making it suitable for casual and everyday wear. TC fabric, while having some moisture-wicking properties, may not be as breathable as CVC fabric.

- Cost: Typically, TC fabric is more cost-effective due to the lower cost of polyester compared to cotton. CVC fabric, with its higher cotton content, may be priced higher but offers enhanced comfort and breathability.

Both TC and CVC fabrics have their unique advantages, making them suitable for different applications and preferences. TC fabric stands out for its durability, wrinkle resistance, and cost-effectiveness, making it ideal for uniforms, workwear, and budget-friendly apparel. On the other hand, CVC fabric offers superior comfort, breathability, and moisture management, making it a preferred choice for casual and everyday wear.

Understanding the characteristics and differences between these fabrics helps manufacturers and consumers make informed decisions, ensuring the right fabric is chosen for the intended use. Whether prioritizing durability or comfort, both TC and CVC fabrics offer valuable benefits, catering to a wide range of textile needs.

Post time: May-17-2024